How to decarbonise cement with one rock

- Anna Reid

- Nov 29, 2024

- 4 min read

Updated: May 14, 2025

Cement is a hard material to tackle when it comes to emissions. Responsible for roughly 8% of global emissions, cement production is lumped together with other essential infrastructure sectors as ‘hard-to-abate’.

Hard does not mean impossible though, with hundreds of innovative start-ups developing solutions that promise to dramatically reduce cement’s emissions profile.

There’s no one single solution of course. Finding the right mix across so many potential options has made it complicated for the industry to navigate.

But now, decarbonising cement can be simplified by using a single rock – olivine.

Olivine holds a range of essential minerals that can support the cement industry to decarbonise completely. Image: Gareth Moon, Ethik Studios.

From this one rock, there is potential for a cement plant to completely decarbonise, with solutions that span clean energy, carbon-free materials and point-source carbon capture.

Before we look at how this one rock can do the job of many, it’s important to revisit why cement is challenging to decarbonise.

Why cement is hard to decarbonise

Before the mid-2010s, ‘hard-to-abate’ was not a common term.

But then the world realised climate change was accelerating, and decarbonisation of the industrial sector became a key lever for rapid emissions reduction at the scale needed.

At the same time, it became clear many fundamental industries we rely upon for our built environment are going to be much harder than others to decarbonise.

Cement is one of these hard-to-abate industries for several reasons:

the production of cement’s main material, clinker, releases a lot of carbon dioxide (CO2),

cement making requires high temperatures, best achieved by burning fossil fuels, and

the economics to change don’t stack up for this low-margin, high volume commodity.

Cement manufacturing may be 'hard-to-abate' but the emissions generated by the sector makes it a challenge we have to overcome. Image: Gareth Moon, Ethik Studios.

Regardless of the difficulties, the cement industry must decarbonise. That means we need to find:

an industry-standard, cost effective and carbon-free substitute for clinker,

technology that captures on-site CO2 emissions but does not interfere with existing plant infrastructure,

a way to power plant operations with adequate clean energy,

solutions that slip seamlessly into existing processes, and

strategies or models that offset the cost of decarbonisation.

It’s a multi-pronged challenge that could be made simpler and more efficient by using olivine.

One rock holds many solutions to decarbonise cement

Olivine is a mineral found in ultramafic rocks. It's one of the most abundant minerals on Earth and a vast amount of it has already been made globally accessible by existing mining operations.

Olivine is found in low-value ultramafic rocks, often already extracted via existing mining operations. Photo credit: Gareth Moon, Ethik Studios.

This commonly found mineral is simple, it contains silica, magnesium and iron. What it doesn’t contain is CO2, so the materials extracted are carbon-free.

The extraction and application of two of these minerals can support four methods to decarbonise cement operations:

Silica can be used as an SCM (supplementary cementitious material) to offset a percentage of the clinker and reduce the overall carbon footprint of the final cement,

In its mineral form, magnesium binds with carbon, making it an effective and efficient material to remove CO2 emissions from industrial smokestacks,

When electrolysis is used in the extraction process, hydrogen is generated creating a source of clean renewable energy.

Captured CO2 carbonates with magnesium, forming magnesium carbonate, a material that can also be used as an SCM to improve properties of concrete.

Combined, these four methods to decarbonise cement can reduce a plant’s operational emissions completely. Plus, cement production volumes can increase between 20-40% by incorporating silica as an SCM.

Olivine can provide a pathway to solutions that decarbonise operations. But what about the economics?

A solution that tallies the emissions and the books

Using just one rock to decarbonise a cement plant across several emission points is strategically emissions efficient. When the production of these olivine-derived materials is co-located with existing cement operations, it becomes cost-efficient too.

Olivine contains a small percentage of highly valuable nickel and cobalt, offering a source of revenue generation for the plant.

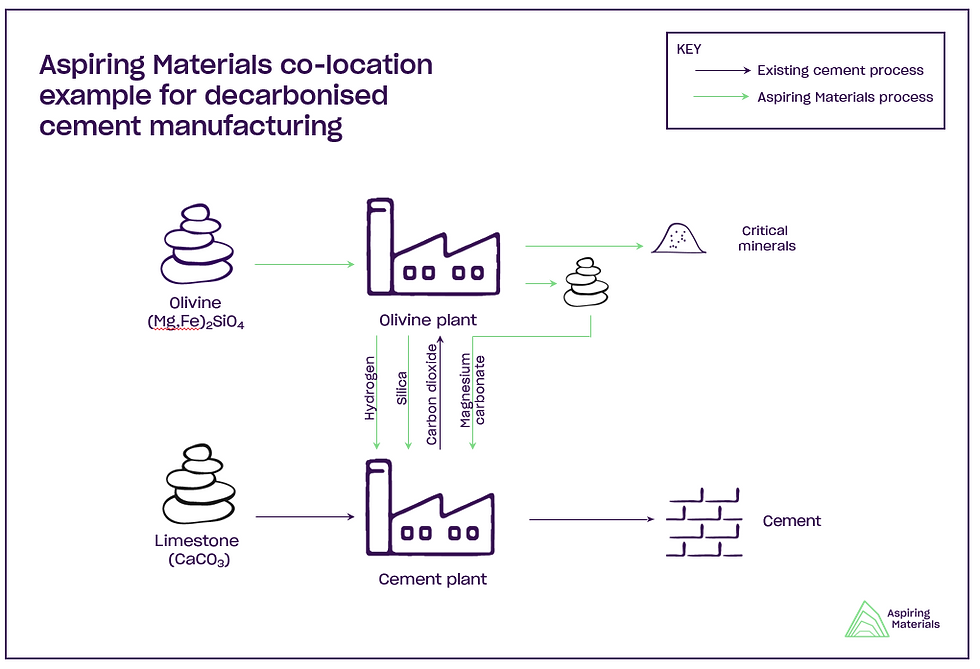

Co-locating an olivine plant with a cement plant provides cement manufacturers a source of clean energy, carbon-free materials and an onsite method for point source carbon capture, plus additional revenue from surplus yet highly valuable materials. Image: Aspiring Materials.

A cement plant that incorporates an olivine extraction operation, like the Aspiring Materials mineralisation process, can:

control the volume and cost of its SCMs,

manage on-site carbon capture and storage,

create a revenue stream through the sale of critical minerals

utilise the resulting magnesium carbonate in cement production or sell it on to concrete producers,

generate carbon credits to offset emissions penalties, and

reduce electricity costs with onsite energy generation.

Plus, existing skills and knowledge are transferable, minimising training as well expanding green job growth opportunities across teams.

A co-location model reinvents cement manufacturing as an operation that offers quality carbon-free materials, and a resilient business that contributes to both climate mitigation and adaptation strategies for our changing world.

The perfect mix for net-zero cement

Decarbonising cement has been a challenging change for manufacturing plants to plan for, balancing today’s production demands with tomorrow’s regulatory penalties.

Now, just one rock could completely transform cement’s emissions impact.

With olivine, cement manufacturing can place itself at the leading edge of industrial decarbonisation and remain an essential pillar of sustainable zero-carbon development.

Aspiring Materials’ olivine mineralisation process is ideally suited for co-location operations with large industrial facilities, like cement manufacturing. Our patented mineralisation process is low energy and zero-waste yet yields high-volume, high-quality materials for industrial applications. Get in touch with us to see how we can help to partially or fully decarbonise your cement operation’s Scope One emissions while maintaining production volumes and profit margins.

Comments